When it comes to Hydraulic Filters, there are a lot of choices to make. In order to make the right decision for your business, you need to understand the different types of Hydraulic Power Units and their applications. You also need to be aware of the different factors that will affect your choice.

In this article, we will discuss the different types of hydraulic power units and the factors you need to consider when making your decision.

-

What are hydraulic power units?

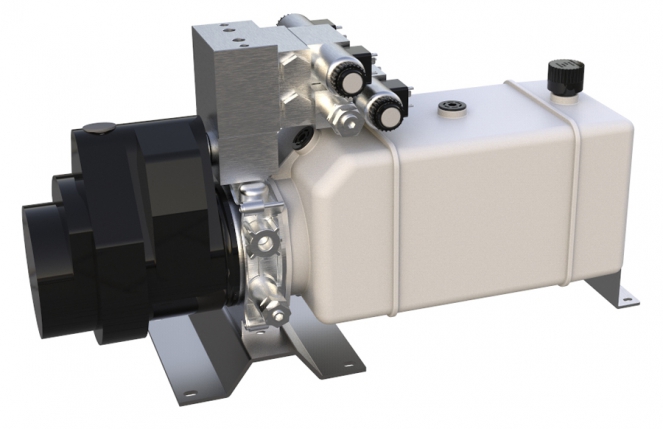

A hydraulic power unit (HPU) is the heart of a hydraulic system. It takes in fluid at one pressure and volume and delivers it at another, higher pressure and volume. The HPU provides the pressure and flows required to power hydraulic actuators and machinery. Choosing the right HPU for your application can be tricky. There are a number of factors to consider, such as available pressure, flow, weight, and dimensions. This article will help you make the right choice for your application.

-

What are hydraulic filters?

Hydraulic filters are a critical component of any hydraulic power unit. They play a vital role in protecting both the pump and the system from damage. As the name suggests, hydraulic filters remove contaminants from the hydraulic fluid. This helps to ensure optimal performance and protect against system failure. There are several different types of hydraulic filters, each with its own set of benefits. It’s important to select the right filter for your application to ensure optimal performance and protection.

-

What is the difference between hydraulic units and filters?

Filters are one of the most important components of a hydraulic power unit. They play a crucial role in protecting your pump and keeping your system running smoothly. There are a few different types of filters, but the most common are the return filter and the suction filter. The return filter is located closest to the pump and removes contaminants from the fluid before it’s returned to the tank. The suction filter is located downstream from the pump and removes larger particles from the fluid before it enters the pump. When selecting a filter, it’s important to consider the flow rate, maximum pressure, and maximum temperature of your system.

-

How to choose a hydraulic unit and filter?

When you’re shopping for a hydraulic power unit, it’s important to select the right type and size. Power units are typically classified by the flow rate and pressure they produce. Be sure to choose a unit that can handle the demands of your application. In terms of filters, it’s important to select the right type and size. Filters protect your hydraulic system from contaminants, so it’s essential to use the right type for your application. Many factors will influence your decision, such as the operating temperature, fluid viscosity, and system pressure.

-

Things to consider when choosing hydraulic filters

When you’re choosing hydraulic filters, there are several factors you need to take into account. The most important are the operating conditions of your machine, the media type, and the maximum allowable pressure differential. You’ll also need to decide on the filter size and type, as well as the housing material. If you’re not sure which filters are right for you, our experts are here to help!

Conclusion:

Choosing the right hydraulic power unit and filter is an important decision that shouldn’t be taken lightly. There are many factors to consider, such as the type of system you have, the type of work you do, and the environment you work in. By understanding the basics of hydraulic power units and filters, you can make the best choice for your specific needs.