If you’re new to the world of hydraulic systems, you may be feeling overwhelmed by the multitude of options available. Don’t worry; we’ve got you covered. In this guide, we will walk you through the key factors to consider when choosing a hydraulic power unit, ensuring you make an informed decision that meets your specific requirements.

Whether you’re looking to power heavy machinery or simply need a unit for a small-scale project, we’ll help you navigate the complexities of Hydraulic Power Units and find the perfect fit for your needs. So, let’s dive in and get started!

Understanding Hydraulic Power Units

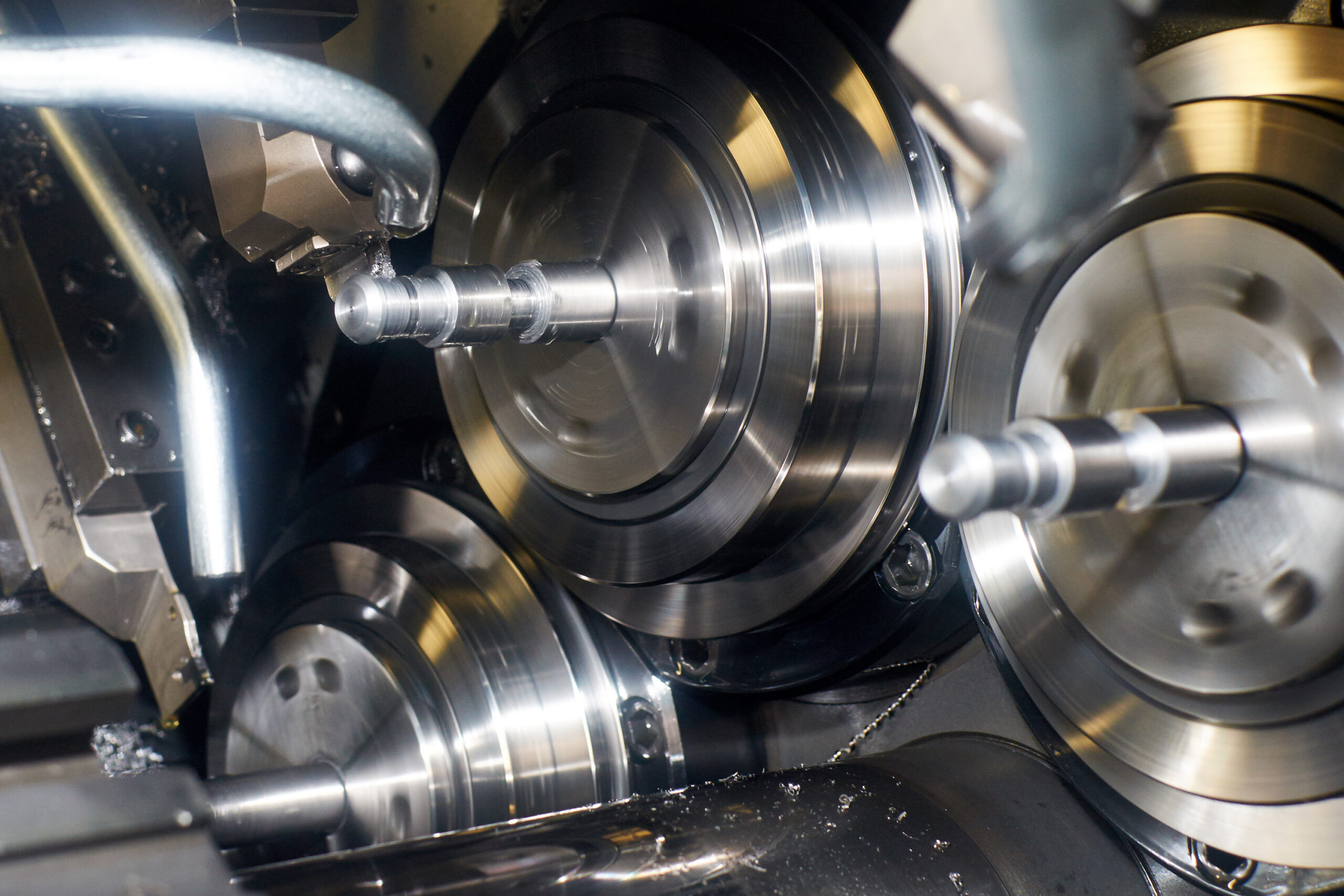

A hydraulic power unit is an essential device in industrial machinery and equipment. It plays a crucial role in converting mechanical energy into hydraulic energy. Consisting of various components such as a motor, pump, reservoir, and control valves, these units are responsible for generating the necessary hydraulic pressure.

The motor, acting as the powerhouse, drives the pump and facilitates the conversion process. Utilised widely in different industries, hydraulic power units are the backbone of many industrial applications.

Different Types of Hydraulic Power Units

When it comes to selecting the right hydraulic power unit for your needs, it is essential to consider the different types available. There are several options to choose from, each with its own advantages and applications.

Electric Hydraulic Power Units

Electric hydraulic power units are known for their efficiency and consistent performance. One of their key advantages is the ability to easily control and adjust their settings to suit the specific needs of the application. These units are typically designed to be compact and lightweight, which makes them easy to transport and install in various locations.

However, it is important to note that electric Hydraulic Ram Repairs require a reliable source of electricity to operate effectively. This is something to consider when selecting the right power unit for your industry, as a stable power supply is crucial for uninterrupted operations.

Engine-Driven Hydraulic Power Units

Engine-driven hydraulic power units are a popular choice for applications that require high power output. These units are designed to handle demanding tasks and provide the necessary force to lift heavy loads or control machinery. One of their key advantages is their ability to be used in remote locations where access to electricity may be limited or unavailable. This makes them versatile and essential in industries such as construction or mining.

Engine-driven units also often come with built-in safety features, such as automatic shut-off systems, to protect against overheating or overloading. However, it’s important to consider that maintenance and fuel costs may be higher compared to electric or hand pump units. Nevertheless, their reliability and power make them a suitable option for industries that require robust hydraulic power solutions.

Hand Pump Hydraulic Power Units

Hand pump hydraulic power units are a straightforward and convenient option, as they only require manual operation to generate pressure. These units are often used as backup or emergency systems in case of a power failure or equipment malfunction. One of their key advantages is that they do not rely on external sources of energy, providing independence in isolated locations or during emergencies.

Note that the pumping action of hand pump units can be physically demanding, which limits their use for prolonged periods or heavy-duty applications. Despite this limitation, hand-pump hydraulic power units are a reliable solution when other sources of hydraulic power are not available.

Factors to Consider When Selecting a Hydraulic Power Unit

When selecting the right hydraulic power unit for your needs, it is important to consider several factors. First, you need to ensure that the power output and capacity of the unit are compatible with the specific requirements of your application. This ensures that the power unit can effectively handle the tasks at hand and provide the necessary force.

Consider the type of hydraulic fluid that is compatible with the power unit and its availability. Using the right type of fluid ensures smooth operation and makes maintenance easier. Additionally, you should also take into account the size and weight of the power unit. It should be suitable for the available space in your facility and should not pose any transportation constraints.

Lastly, assess the reliability and durability of the power unit. Look for units that have a track record of dependable performance and are backed by good technical support. Availability of spare parts is also a critical factor to consider for long-term operation and maintenance. By carefully considering these factors, you can select a hydraulic power unit that will meet your needs effectively and efficiently.

Budget and Maintenance Considerations

When selecting a hydraulic power unit, it is crucial to consider not only the initial cost of purchasing and setting up the equipment but also the ongoing expenses for maintenance and repairs. Factor in the cost of regular inspections and preventive maintenance to ensure the longevity and efficiency of your equipment.

It is also important to evaluate the total cost of ownership over the lifespan of the equipment, including energy consumption and any additional expenses for upgrades or replacement parts. Although it may be tempting to opt for cheaper options, keep in mind that investing in quality equipment upfront may result in reduced maintenance costs and higher overall reliability in the long run.

Installation and Maintenance Tips for Hydraulic Power Units

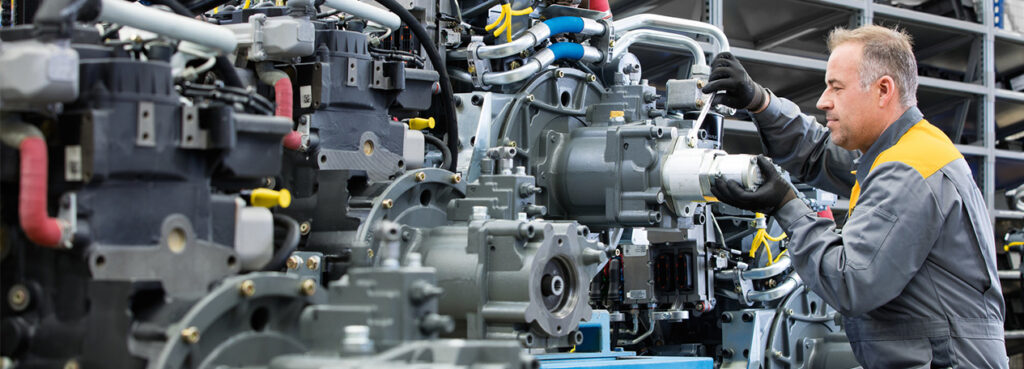

When installing a hydraulic power unit, it is important to follow proper installation techniques and best practices to ensure optimal performance. This includes correctly connecting all system components, such as valves and actuators, and ensuring proper alignment and mounting.

Take into account factors like available space, ventilation, and noise considerations to create a safe and efficient working environment. Regular maintenance is also crucial for the longevity of your hydraulic power unit. It is recommended to perform routine checks and troubleshooting as needed to identify and address any potential issues before they escalate. This includes inspecting hoses and fittings, checking fluid levels and quality, and monitoring for any abnormal noises or vibrations.

Keeping the fluid in your hydraulic power unit clean is essential for its efficient operation. Contaminated fluid can cause damage and reduced performance, so investing in proper filtration systems and regular fluid analysis is important. This ensures that the fluid meets the required cleanliness standards and helps prevent costly downtime and repairs. Furthermore, operators should receive adequate training on how to operate hydraulic power units safely. Implementing proper safety precautions, such as using protective gear and establishing clear operating procedures, is crucial for minimising the risk of accidents.

Ongoing training and refresher courses should also be provided to keep operators updated on safety guidelines and best practices. By prioritising proper installation, regular maintenance, fluid cleanliness, and operator safety, you can maximise the performance and longevity of your hydraulic power unit.

Conclusion

Selecting the ideal hydraulic power units for your needs is a critical decision with far-reaching implications for your machinery’s performance and efficiency. By assessing your specific requirements, understanding the key components, and considering factors like flow rate, pressure, and fluid type, you can make an informed choice.

Keep an eye on future growth and adaptability to ensure your investment stands the test of time. Whether you’re operating in manufacturing, construction, or any other industry, choosing the right hydraulic power unit is about more than just hardware – it’s about powering your success. So, take your time, do your research, and make a choice that empowers your operations for years to come.