If you’re looking for a way to reduce the starting kick of your electric motor, you may want to consider installing a variable speed drive (VSD). A VSD is an electronic device that can regulate the speed of an electric motor. Controlling the amount of power supplied to your electric motor can reduce the amount of amperage drawn upon startup and when operating normally. This allows you to use less electricity while reducing maintenance costs over time on older motors. In this article, we will discuss how they work, what types available today and their benefits and disadvantages.

What is a Variable Speed Drive (VSD)?

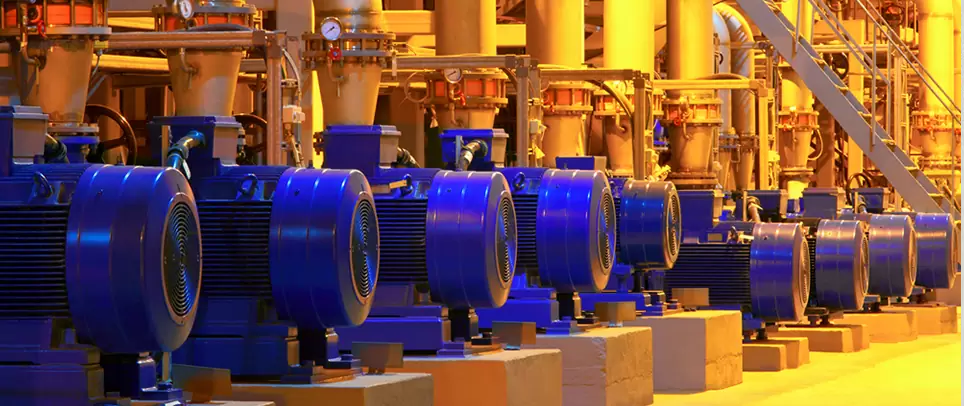

A variable speed drive is a device that allows you to control the speed of your motor. It is used in many applications, including construction, mining, and manufacturing. A variable speed drive can control a wide range of motors from 1/2-HP to over 2,000 HP. Variable Speed Drives are also called Variable Frequency Drives (VFDs) or VSDs for short.

How does a VSD reduce the starting kick of electric motors?

To understand how a VSD reduces the starting kick of electric motors, it is important to understand what a VSD does. A Variable Speed Drive (VSD) is an electronic device that controls the speed of an electric motor. This means it adjusts the voltage, current, or frequency at which an electric motor runs. The goal of using a VSD is usually to reduce wear on an electric motor by reducing its startup torque and current requirements without affecting its maximum speed.

This process works by lowering the voltage applied to an electric motor’s windings so that they are not under as much strain when they start up. This causes less heat buildup in those windings during their initial startup period, reducing their temperature rise while they reach full speed.

What are some benefits of using a VSD on electric motors?

There are several benefits to using a VSD on electric motors.

A VSD will reduce the starting kick of an electric motor by reducing its load when you start it up, making it easier to start and reducing wear and tear on the motor.

A variable speed drive can also reduce the likelihood that your motor overheats due to heavy use or high ambient temperatures, thus extending its lifespan.

This is especially useful in applications where motors must run nonstop for long periods, such as in refrigeration systems or manufacturing facilities that require continuous operation for days or weeks at a time; with a variable speed drive, there’s no longer any need to worry about tripping breakers or burning out motors from overuse.

How can you tell whether or not a motor needs a VSD installed to reduce the starting kick?

This is a question you need to ask yourself before installing a variable speed drive. First and foremost, if your motor is running at its full speed (or close to it), then there is no way for it to experience starting kick because the motor has already achieved its maximum velocity. If this is true for your application, installing a VSD will not reduce startup current or power consumption.

Suppose your application calls for constant load variations or variable speeds. In that case, this could indicate that the motor needs some type of feedback loop control system, such as a variable frequency drive (VFD) or variable torque converter (VTC). Either way, the VFD/VTC prevents any potential starting kick by constantly monitoring operations in real-time and adjusting accordingly so that they meet specific performance criteria during operation while also reducing operating costs by eliminating unnecessary energy usage.

Conclusion

If you’re using a VSD for reliability, use one that has overload protection or failsafe levels (if you’re using a simple VSD) because cutting out a motor’s power in critical situations could actually result in electrical problems. You should also check the wiring diagram before trying to install your VSD with another piece of equipment, like an alternator or a regulator/rectifier, because they need different gauges of wire than their stationary counterparts. By understanding how a variable speed drive can reduce motor starting kick, you can make your electric motors last longer, operate more efficiently and save money in the long run.