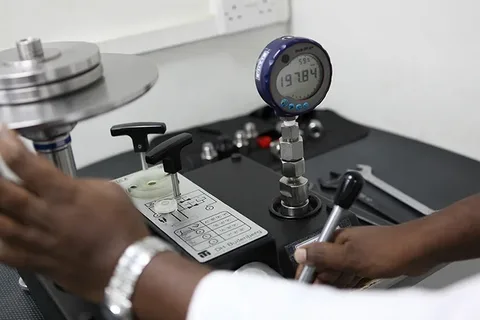

Calibration is the process of verifying that instruments are working properly and accurately. This is important for the precision, accuracy, and repeatability of your test results.

If you’re using an instrument that isn’t calibrated, it could be causing issues with low reproducibility and precision.

In this blog post, we’ll discuss why Instrument Calibration is crucial for performance, how it helps improve your workflow, and how to choose a calibration service provider.

Ensures accuracy and reliability

Calibration ensures that the instrument is operating as it should, calibrated to correct standards, and reliable for use. It also ensures that instruments are accurate.

Instruments used in laboratories need Instrument Calibration on a regular basis so that they can provide consistent results for your experiments.

If you have an instrument that has not been calibrated, then you may be getting faulty data from your experiments which could lead to incorrect conclusions or even damage your research project altogether!

Detects and corrects errors

Calibration helps to detect and correct errors. Errors can be detected by comparing the instrument reading to a known value, and they can be corrected by adjusting the instrument.

Calibration is an important part of maintaining accurate equipment because it ensures that your measurements are reliable without constant re-measurement. A calibrated instrument will give you consistent results over time, which makes it easier for you to compare data from different tests or experiments.

Calibration also helps to prevent damage to your equipment. If the instrument is not calibrated properly and you make an incorrect measurement, it can cause damage to your equipment or even harm people nearby.

Increases efficiency

Calibration is a critical step in the maintenance of any instrument. It ensures that your equipment is performing as expected, allowing you to make accurate measurements and obtain reliable results.

Calibration reduces the time required for calibration and check-up tasks, which can significantly reduce the costs associated with maintaining your instruments.

This also helps ensure that your employees have enough time for other important tasks like troubleshooting or troubleshooting when an instrument fails during use.

Complies with regulations and standards

Calibration ensures that your instrument is fit for purpose. It ensures that the device complies with local and international standards, as well as regulations. For example, calibrating a pH meter will ensure that it measures pH levels accurately so you can use it to test water samples.

Calibration also makes sure that your equipment is safe to use in a laboratory setting: if you don’t calibrate your balance regularly, then there’s a chance it could break down or cause damage due to incorrect readings (for example by weighing something incorrectly).

Conclusion

In conclusion, it is clear that Instrument Calibration is an essential process for the performance of instruments. Without proper calibration, the readings will be inaccurate and may lead to inaccurate results.

It is therefore important that you calibrate your instrument regularly so that you can always get accurate readings from it.